by RON JONES

•

16 April 2020

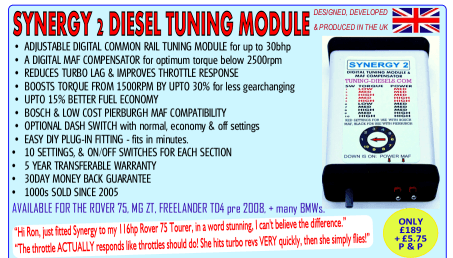

INITIAL CHECKS A) DISCONNECT THE VACUUM SUPPLY AND DRIVE THE VEHICLE. THE BOOST WILL BE POOR BUT MAY INCREASE AT HIGH RPM. IF IT GETS TOO HIGH THEN YOU NEED TO LENGTHEN THE ACTUATOR BECAUSE THE DGBS WILL NOT BE ABLE TO LOWER IT. see note below. B) CONNECT THE DGBS, LEAVE ON SETTING 0. START THE ENGINE AND OBSERVE THE ACTUATOR ROD. YOU SHOULD AIM FOR IT TO PULL IN ABOUT 2CM AT THIS STAGE. If not, change switches 5,6,7,8 to a higher setting, eg switch 7 on, rest off. Next, drive the vehicle and observe the boost on your gauge. If max boost is not high enough, slightly turn the top adjuster to the right. If you want more low down boost, use a higher setting of switches 5,6,7,8 and then alter the top adjuster to control the maximum boost which is usually between 1800-2200rpm on most diesels. IT IS NOT NORMAL FOR THE ACTUATOR ROD TO PULL IN FULLY OR AGAINST THE VNT LEVER END STOP. THIS WILL LEAD TO TURBO LAG AND FLAT SPOTS. ACTUATOR ROD LENGTH SETTING If fitting a turbo off another engine, the actuator rod will have been factory set for that engine. This means you may have to adjust the linkage either way. So if you find the boost is too high on all the switch settings, you can try adjusting the nut to lengthen the rod. The converse also applies if the max boost is low even on max setting, however the adjustment should be small and assumes there is still some free movement of the vnt lever – ie its not already against the end stop.